a free bend test|free bend test welding : custom The bend test is a simple and inexpensive qualitative test that can be used to evaluate both the ductility and soundness of a material. It is often used as a quality control test for butt-welded joints, having the advantage of simplicity of . 21 de jun. de 2022 · The actors from the drama "Sh**ting Stars" share their real-life friendship, their ideal manager, and their future plans. They also talk about their roles, .

{plog:ftitle_list}

10 de fev. de 2024 · RF Online, Rising Force Online, RFO. Download and Play the Ultimate Fantasy Sci-fi 3D Online MMORPG for Free. Explore the NOVUS Galaxy. Master Might, Magic, and Mech and Become Leader of Your Race.

The bend test is a simple and inexpensive qualitative test that can be used to evaluate both the ductility and soundness of a material. It is often used as a quality control test for butt-welded joints, having the advantage of simplicity of . The angle of bend can be measured while the specimen is under the bending force (usually when the semi-guided bend test is employed), or after removal of the force as .How much or how little a material will bend can determine its suitability for use in a product or structure. A bend test measures flexural strength, strain or stress to find out whether that material is a good choice for the intended end use.A welded specimen is subjected to bending forces to determine its capacity to sustain deformation without fracture or failure. We provide a full explanation of the welding bend test .

Free Bend Test measures the ductility of the weld metal in a butt joint in a plate or pipe in terms of elongation percentage. The thickness of the specimen is the same as that of the plate or the pipe, the width is 1.5times the . Free Bend Test This physical weld-free bend testing approach is designed to judge the ductility of the metal deposited in a weld joint. The specimen for this testing is procured by machining from the welded plate with .

Free Bend Test. The free bend test is used less often than guided bend tests because many variables are challenging to control. It’s first necessary to perform what’s called an initial bend by clamping the test bar in .Single-edge notch-bending specimen (also called three-point bending specimen) for fracture toughness testing.. The fracture toughness of a specimen can also be determined using a three-point flexural test. The stress intensity factor at the crack tip of a single edge notch bending specimen is [3] = [() / / + / / + /] where is the applied load, is the thickness of the specimen, is . Join for free. Public Full-text 1. Content uploaded by Deniz Yalcin. Author content. . ASTM D2344 bend test xture. ASTM C1161 bend tes ng xture. ASTM C158 Bend T es ng – Glass.The three standard bending strength tests are the cantilever beam bend test, the three-point bend test, and the four-point bend test. European Standard EN 12384 specifies a bend test to determine the modulus of elasticity in bending. Japanese Industrial Standard JIS 3130 specifies two tests to determine the elastic limit of spring plate or .

Free-bend test; Bend and flatten test; There are no standardized terms for reporting bend test results for broad classes of materials; rather, terms associated with bend tests apply to specific forms or types of materials. For example, a bend test for ductility of welds is given in ASTM E-190. Advertisement.

welding bend test procedure pdf

Free Bend Test. The free bend physical weld testing approach has been devised to measure the ductility of the weld metal deposited in a weld joint. A physical weld testing specimen is machined from the welded plate .Enhance your knowledge of welding, cutting, and fabrication with free and accessible webinars on a variety of topics, including welding best practices, tips for using ESAB products, new product launches, and more, presented by trusted ESAB experts. . The welding bend test is a popular mechanical testing method for determining the ductility .Results from bend testing are typically reported as the smallest R/T (the ratio between the die radius and the sheet thickness) that results in a crack-free bend. Many steel companies report minimum bend test limits for various grades and certain automakers include minimum bend test requirements in their specifications as well.The bending test achieves more accurate measuring results for fiber-reinforced plastics. However, the checking fixture used is more complicated to handle and more expensive to purchase. According to DIN EN ISO 14125, 3- and 4-point bending test setups can also be used for these materials. They cause the specimen to break.

Small-scale bending tests (Fig. 7) provide a simply fixable set-up for anchors characterization in combined shear-bending and even in equilibrium critical application.It is probably the closest combination of stresses to simulate a real-scale bended structure, which is possible through a small-scale test [97].In this case, recovery of characterization data from the .

4.1 The bend test shall be carried out in testing machines or presses equipped with the following devices: 4 b) 4 Bending device with two supports and a mandrel as shown in Fig. 1, Bending device with a V-block and a mandrel as shown in Fig. 2, and Bending device with a clamp as shown in Fig. 3. 1 FIG.

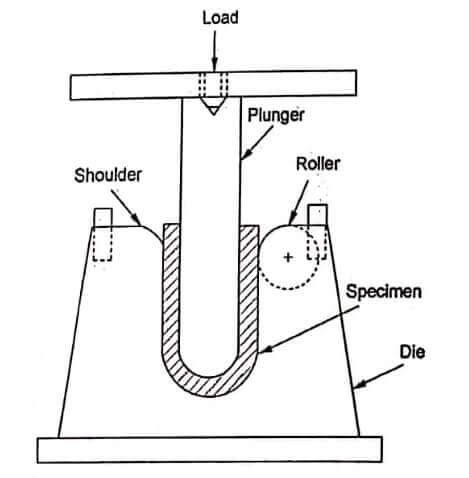

Figure 7-61.-Free-bend test . Figure 7-62.-Guided-bend test jig. 1/16 inch from each edge of the weld metal, as shown in figure 7-61, view B. Measure the distance, in inches, between the lines to the nearest 0.01 inch and let the resulting measurement equal (x). Then bend the ends of the test specimen until each leg forms an angle of 30 degrees .

guided bend testing equipment

free bend test welding

bend test specimen size

B1. Longitudinal Guided-Bend Test (See Part A1, section 7.6, Fillet Weld Root Bend Test.) 1. Scope 1.1 This section covers the bend testing of fillet welds. The standard gives the requirements for guided bend test specimen preparation, test parameters and testing proce-dures, but does not specify the requirements or accep-tance criteria.ASTM E290 is divided into four methods for bending the specimen: Guided Bend; Semi-Guided Bend; Free-Bend; Bend and Flatten. These tests are performed by supporting the two ends of a specimen while loading it at the center with a mandrel or plunger. The test is completed when the designated angle of the bend, or other specified condition, has .

3. Free Bend Test. This physical weld-free bend testing approach is designed to judge the ductility of the metal deposited in a weld joint. The specimen for this testing is procured by machining from the welded plate with the weld that came across as shown in A, figure.

During a bend test, the load is applied to the center of the specimen, causing it to bend. . The three common types of bend tests are guided bend tests, free bend tests, and semi-guided bend tests. What material has high flexural .

The BEND TEST! One of the tests used to determine the soundness of weld metal is a bend test. A bend test can take a few forms and may have to meet different requirements. For the purpose of this short piece .The ends of the sample are pressed together without applying any force to the bend itself in a free bend test. Last but not least, ASTM E399 is a popular fracture toughness test that involves loading a sample with a precracked .4.1.3.1 Type 1, 180° free-bend test. 4.1.3.2 Type 2, flat-on-itself free-bend test. 4.1.4 Bend-and-flatten Test 4.2 Aguided-bend test for ductility of welds is described in Method E190 and may be used for flat-rolled materials when specified by the .

Theory Behind 3 Point Bend Test. Three-point Bend Test procedure and working is derived from the theory of bending of the simply supported beam as explained above. To carry out the calculation of the test results after conduction of the 3-point bend test, one needs to rely on the theory of bending of the beam. Theory of Bending MTS Senior Application Engineer, Garrett Georgeson, demonstrates a 3-point bend test.Learn more about bend testing applications and common bend test standard. The free bend test is used less often than guided bend tests because many variables are challenging to control. It’s first necessary to perform what’s called an initial bend by clamping the test bar in a vise and hammering it until it partially bends. Once the tested bar is bent enough for both ends to fit into a vise safely, the sample is .

Evade, defend, and neutralize nonviolently Stand your ground, block attacks, and use all your strength Heavy offense, keep moving, and dodge while attacking Counterstrike instead of initiate, then use their force against them

The bend test is a straightforward and low-cost qualitative method for determining a material's ductility and structural integrity. A mechanical test called bend testing is frequently used to evaluate a material's ductil ity and structural integrity, especially with regard to metals and alloys. This test provides important information about a material's capacity to sustain applied loads .Mechanical test methods that are applicable to welds and welded joints are described. For each testing method, informa- . related to tension tests, shear tests, bend tests, fracture toughness tests, hardness tests, break tests (nick and fillet welds),

tubing wall thickness measurement

The bend test than can be clamped entirely in the vice. Either a force using a hammer or from the vice can be used to make the final bend. Due to the fact that in free bend, as the bending parameters can not be controlled, this type of bend does not reflect good quality results, and hence free bend test is not used too much.

Level 1: Bend either 1 or 4 draw. (whichever one is easiest for you). For levels 1, 2 and 3, you don’t need to bend in tune. Level 2: Bend all the draw notes from 1 to 6. Again, you don’t need to bend in tune yet. Level 3: Bend 8, 9 or 10 blow. (Just bend them. Don’t worry about playing them in tune until later.)Central Oregon Community College Campus - Bend 2600 NW College Way, Bend, OR 97703 ; Monday through Friday 7 a.m. to 5 p.m. Hoodview Church of God (11/19/2021) 1530 MT Hood Ave, Woodburn, OR 97071 ; Monday through Friday , 8 a.m. to 3 p.m. Jackson County EXPO. 1 Peninger Rd, Central Point, OR 97502 Sunday through Thursday, 8 a.m. to 3 p.m.

ultrasonic measurement of pipe wall thickness

10 de out. de 2012 · Disney's Tinker Bell and The Secret of The Wings - available to own on Blu-ray and DVD from the 8th April 2013.Subscribe to Disney UK: http://bit.ly/subscrib.

a free bend test|free bend test welding